FINISHES

Advanced plastic techniques.

To offer unique finishes it is necessary to carry out a series of processes once the piece is printed; To find out which is the most suitable for your project, you will then have part of our budget model which will help you to orient yourself to your request and needs (Ex: Printed parts, Post + Primer + Final paint + Varnish, etc.)

How it works?

1

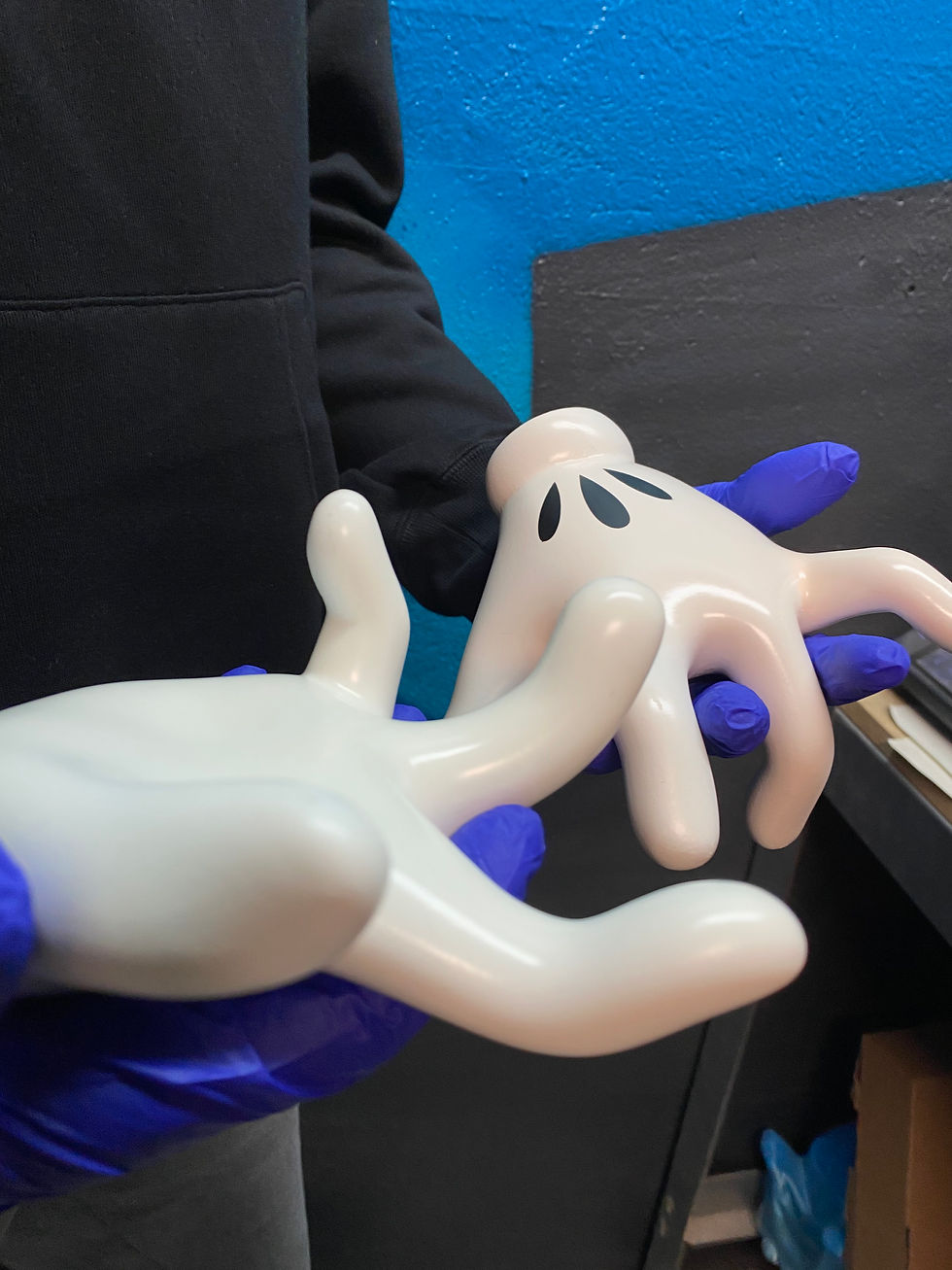

Sanding

When a figure is printed using FDM technique, must be post processed later in order to get the premium quality we all desire. That's why sanding and assembling are essential to get the perfect figure.

2

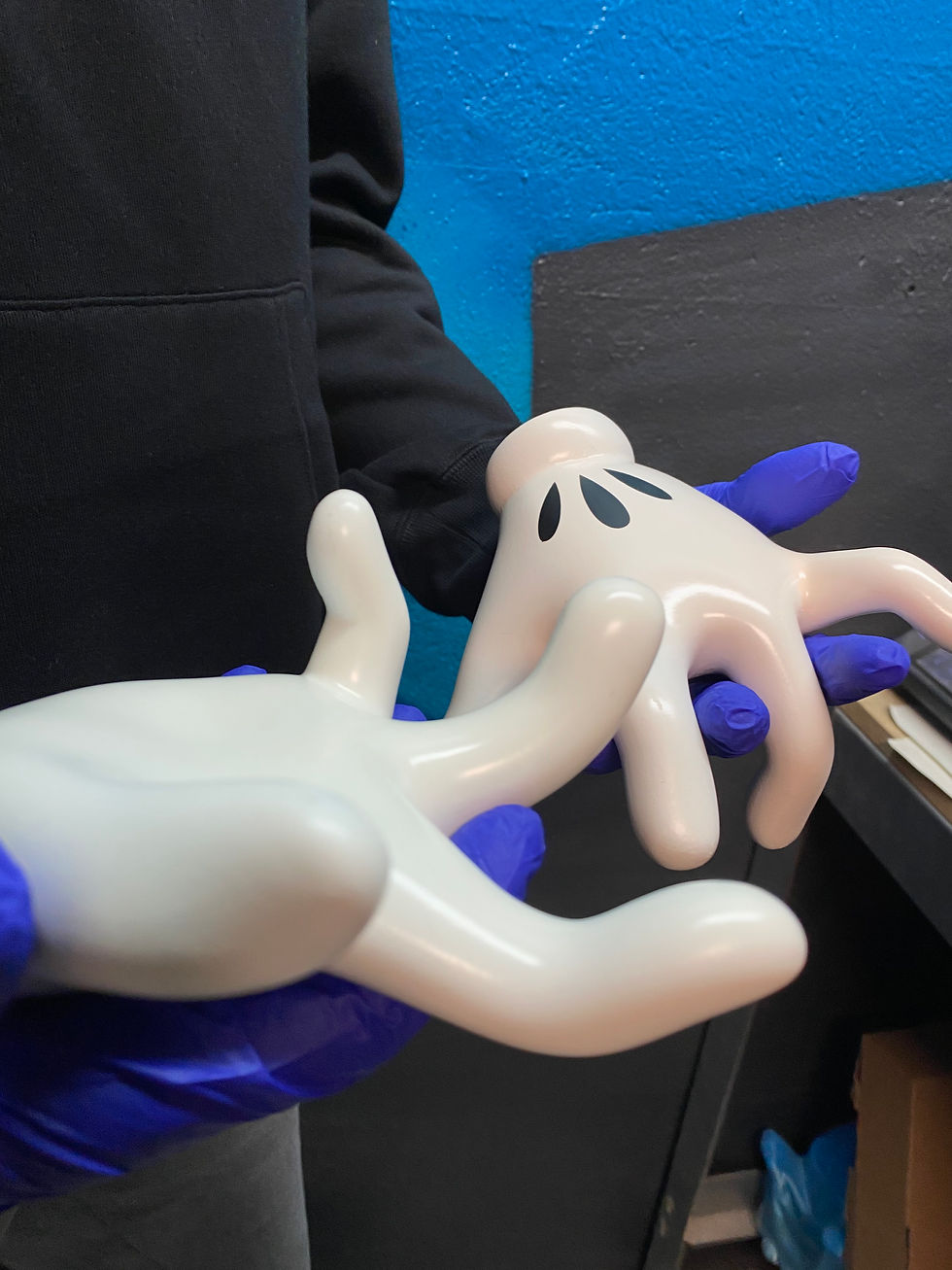

Primer

To get the best painting finish, it is crucial to prime the figure before painting it, since most materials do not offer a good adherence to the paint. This process will help us smooth the figure and allow us to paint it with the best results.

3

Paint Finishes

We offer the best painting quality possible adapting each project to the customer needs. Our team will check your needs and offer you the best possible solution to get the perfect figure, getting the exact RAL color or the desired effect.

Sanding

Since FDM techology works around printing layer after layer it is impossible to get a completely smooth surface. For that reason we must sand the figure to get rid of the layers. This process will be executed using various types of sanding paper, starting from a low grit sandpaper up to the highest grit sandpaper in order to get the smoothest surface.

Primer

Once the figure has been perfectly sanded and, in case it was neede, assemble, we must prime it. This is necessary for two different reasons. The first, and most important, reason is that most printable materials do not offer a good adherence to the paint, meaning it would fall off or would not get the desired texture. The second reason is it adds an extra protection layer and allowing us to get the best quality of finish.

Finishes

We have a top notch team of painters, who will guide you through the process of painting, giving advise in what kind of paint would best fit your desires, being a simple RAL color or having more intricate patterns or achieving the desired effect. We offer all type of finished products, get in touch with us and get the best product possible.

Given that we adapt to the client's needs, we offer the client the possibility of starting the process from the point they want:

You can choose over

Ral Colors

Before modifying a part, we make sure to optimize its triangulation.

Chamaleonic

Swap and match different pieces in 3D. When printing multiple objects, it is important to use the available space efficiently.

Stencils

In order to create the necessary shells.

Pinstripping

For an element to be visible after 3D printing, it must have a minimum wall thickness or detail size, which depends on the 3D printer and 3D printing technology.

Varnishes

For functional pieces that require a certain resistance, we will add thickness to the walls to hollow out your design; can be a good way to save a considerable amount of material and time.

Metal effects

Various ways to separate a piece from a mesh.

Stone Effects

Advanced functionality, necessary for the work of 3D sculptures. (Moves, Displaces and translates in 3D space).

Oxide & Fx

We offer several advanced methods for mesh error repair.

Hyperrealism

For functional pieces that require a certain resistance, we will add thickness to the walls to hollow out your design; can be a good way to save a considerable amount of material and time.

For this reason we offer the client the possibility of "improving" or optimizing their design so that the best possible printing result is left.

Since this service varies greatly in difficulty, a study on our part will be necessary before giving a budget.